DART-RICH is a national high-tech enterprise . The technology center is the R&D and design center of DART-RICH, the enterprise technology center recognized by Jiangsu Province and the engineering technology research center of Jiangsu Province. The Technology Center consists of Fan Research Institute, Compressor Research Institute, Process Research Institute and Commonality Research Institute, and a postdoctoral workstation of fluid machinery.

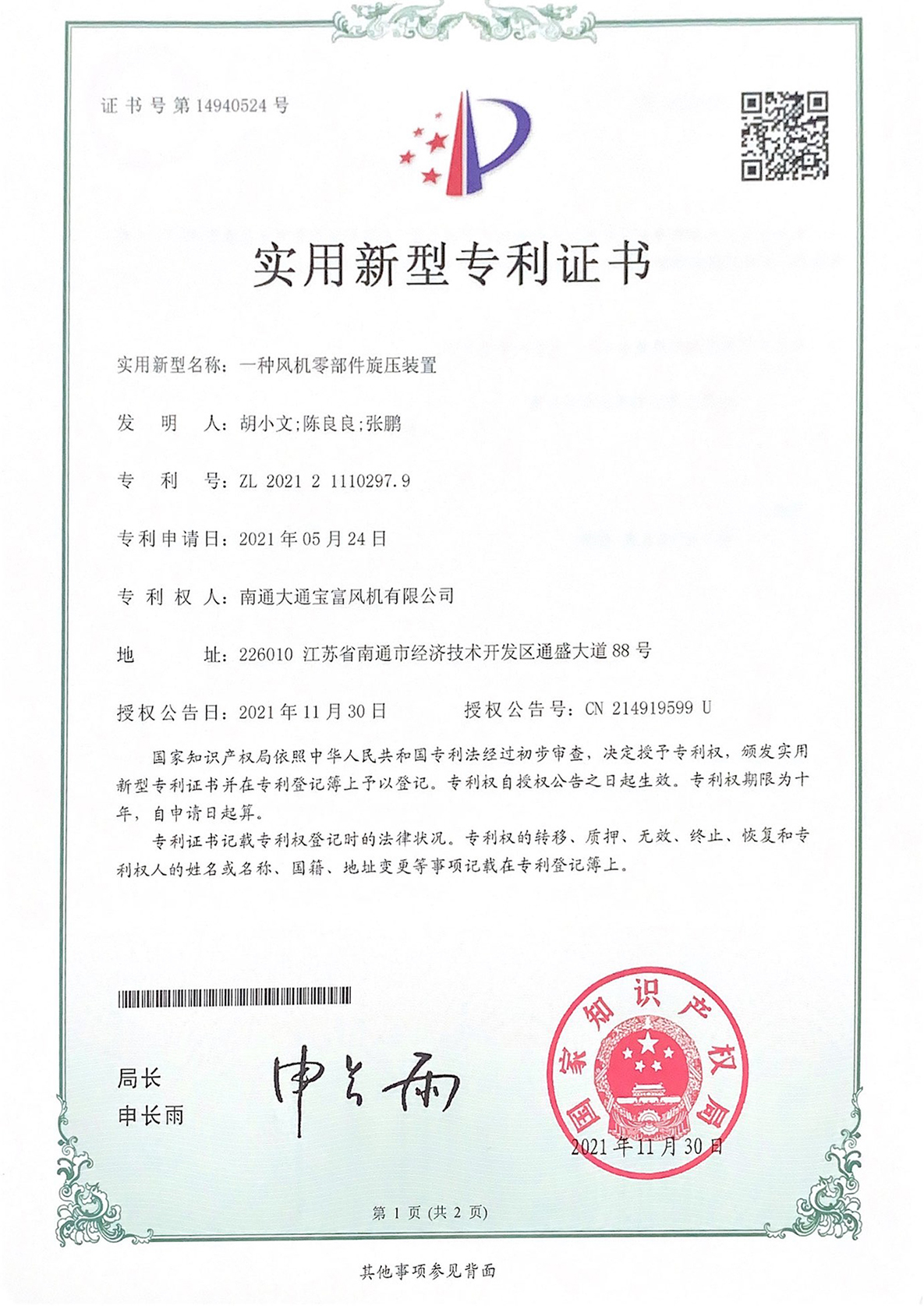

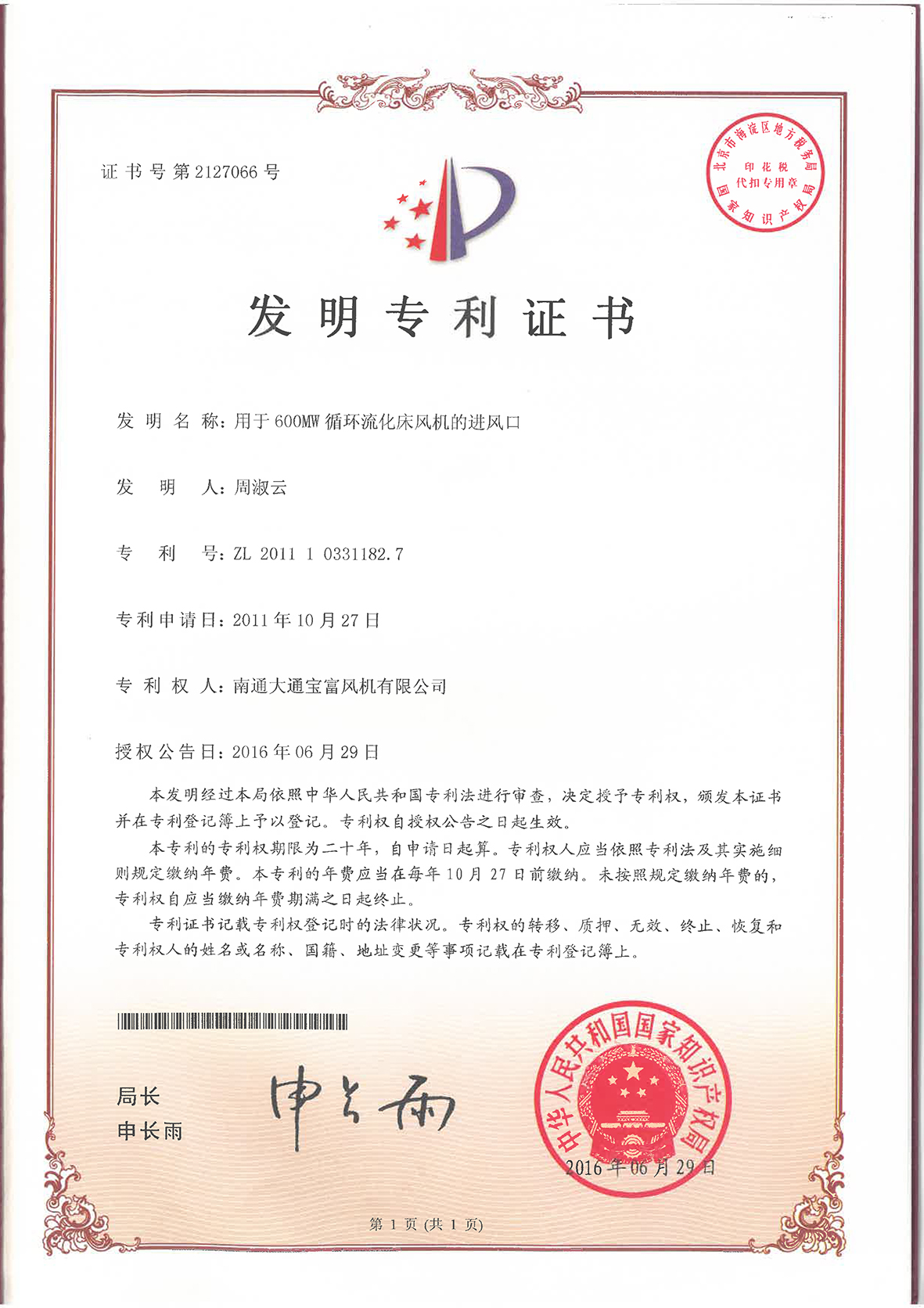

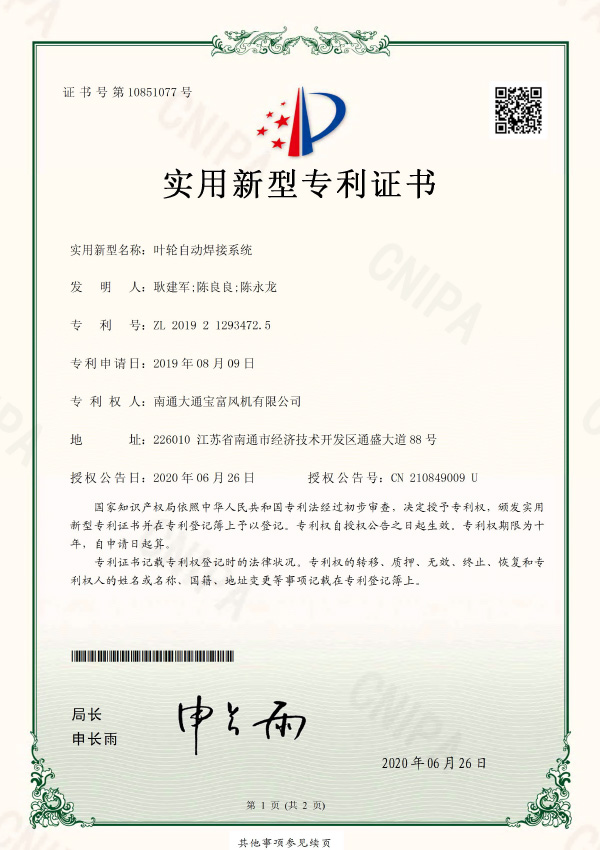

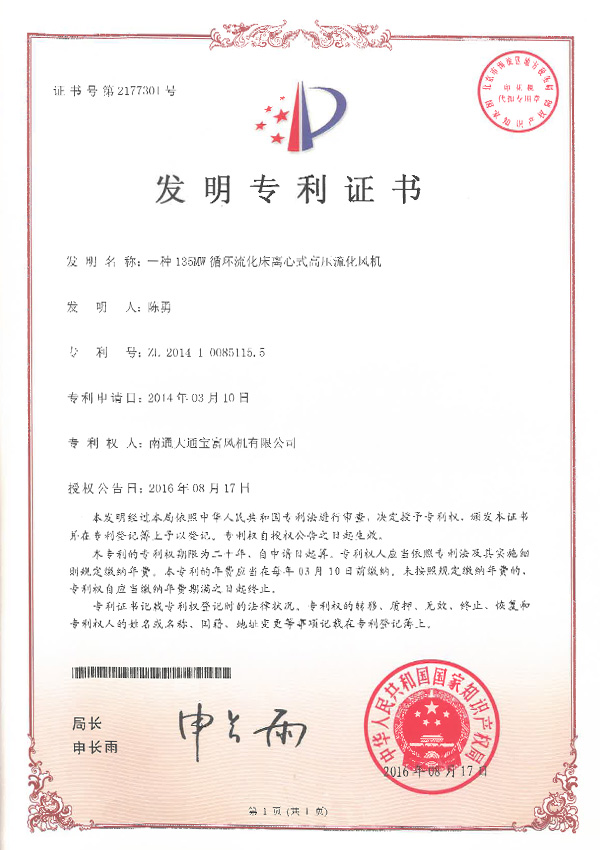

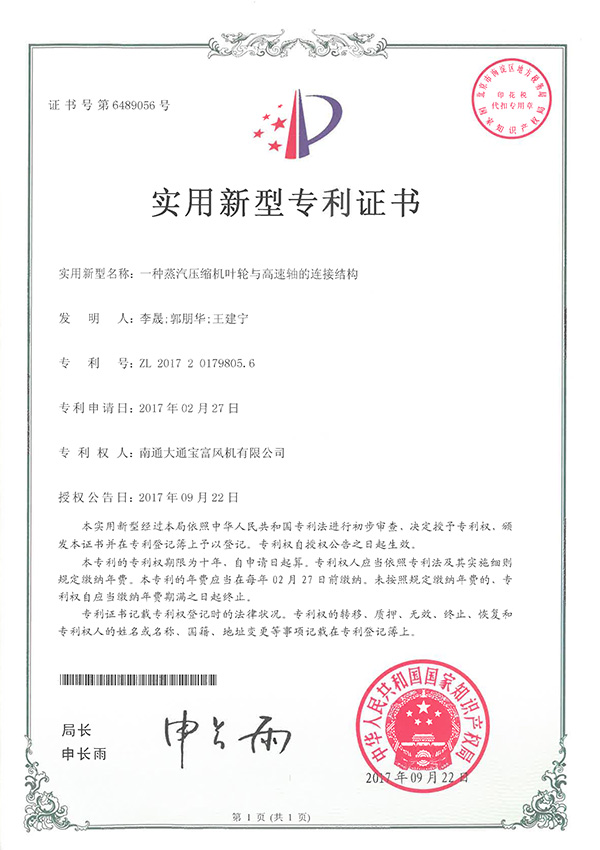

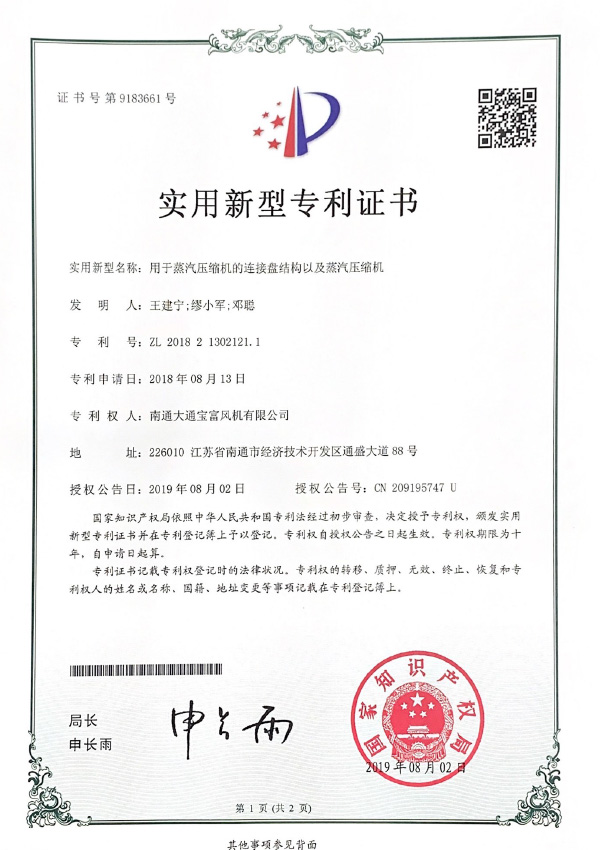

Our company always adheres to the product development path of combining “production, study and research”. It focuses on technical research and development investment. It has established long-term close cooperation with well-known universities and research institutes in China, including Zhejiang University, Tsinghua University, Xi 'an Jiaotong University, Xi 'an Institute of Thermal Engineering, Hefei General Machinery Research Institute and Shenyang Blower Research Institute. The company has successively established research and development institutions such as "Postdoctoral workstation", "Jiangsu enterprise technology center" and "Jiangsu engineering technology research center", and has been qualified as the "National high-tech enterprise".

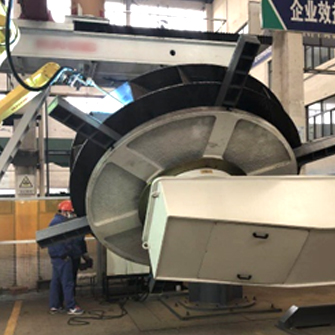

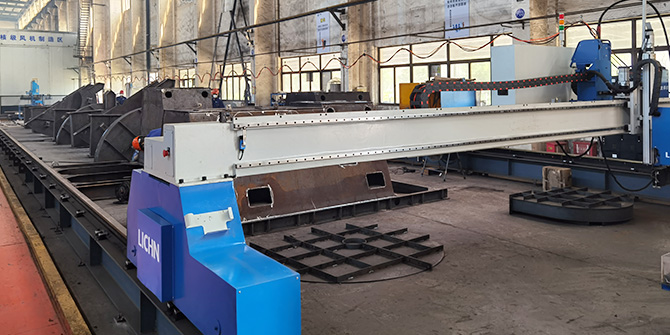

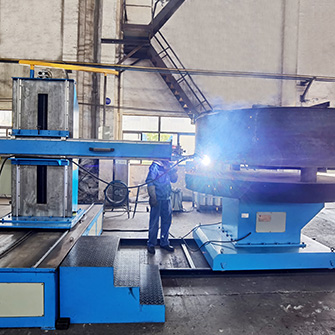

The construction area of production workshop in DART-RICH headquarter factory is about 80,000 m2, and that in Hunan factory is about 13,000m2. The company has been committed to the construction of intelligent manufacturing, and has introduced several sets of high-end intelligent manufacturing equipment from Germany, Denmark and other countries. There are more than 400 sets of advanced manufacturing equipment such as German Hammer five-axis machining center, CNC turning and milling compound center, impeller automatic welding robot, fan volute copying welding machine, gantry vision welding system, Danish automatic spinning machine, large laser cutting machine, CNC flame cutting machine, CNC metal cutting machine tools, CNC bending machine, edge milling machine, rolling/hydraulic press, etc., which fully meet the manufacturing requirements of all kinds of products such as fans, blowers, compressors, nuclear fans, etc., and ensure the full-cycle accurate processing and manufacturing from a steel plate to a complete product.

Our Inspection & Test Center is mainly engaged in fan performance test, raw material analysis and testing, steel and forged piece testing, measuring instruments management and other related works. In June 2024, our testing center obtained CNAS laboratory accreditation certificate. We have more than 40 sets of advanced sophisticated inspection and testing equipment, and fan impeller over-speed test platform, fan rotor operation and over-speed test platform, fan operation performance test platform, duct performance test platform, nondestructive testing room, mechanical properties of materials and physical and chemical laboratories. To realize the inspection and test of incoming raw materials, processing process inspection, parts inspection and test, product delivery test and other whole process, to ensure that each product is produced under strict quality control, and finally qualified products to customers.

We have a professional pre-sales support service team to provide you with professional consulting services, and quickly provide you with the best solution according to your needs.

We have eight marketing service centers in China and a global sales and service network. Make sure to respond within 2 hours after receiving the customer service demand notice, and arrive at the customer site within 8 hours in Jiangsu province and 24 hours outside Jiangsu province. We adhere to the "intelligent service" with the aim of "more accurate and comprehensive", and provide you with 24-hour round-the-clock service in the process of project implementation, and provide customer on-site and the company training. We can customize the most suitable maintenance plan and system optimization solutions such as energy-saving renovation of wind system for you according to your needs, and provide you with full-life service.

We have a self-developed IoT (Internet of Things) cloud platform, which enables remote detection, early fault warning and consultation of equipment operation conditions to ensure the safe and stable operation of your equipment.

Process screen (PC)

Historical Data curve (mobile)

Data trend screen (PC)

Fault Information Management (mobile)

Copyright ? 2023 Nantong Dart-Rich Fan Co., LTD. 蘇ICP備11054767號(hào)-3 Technical support:SUEASY